The Evo8

I've always been fascinated by square split cane rods. It's not the look of the square shape – it's the physical properties of the square that convince me. I'll even admit – but this is simply a matter of taste – that a hexagonal split cane rod probably looks more elegant and lighter. Especially with longer rods that have somewhat sturdier handles, a quad can quickly appear rather heavy.

Compared to a hex rod, the quad is slightly lighter and, with the same taper, has a somewhat stronger backbone for long-distance casts. That's one of the conclusions from the comparative test in my rod series.

Evo8

The quad bikes are repackaged

A square rod looks elegant – as long as the cross-section isn't too thick. If the cross-section increases, as is the case with longer and heavier rods, then even a square rod, with its broad sides, appears significantly heavier than a hexagonal one. I find this off-putting.

The obvious solution is simple: cut off the corners!

However, we now know that it is precisely in the outermost parts of the bamboo that we find the highest density of strong fibers. Therefore, for physical reasons, planing off the corner cannot be the solution.

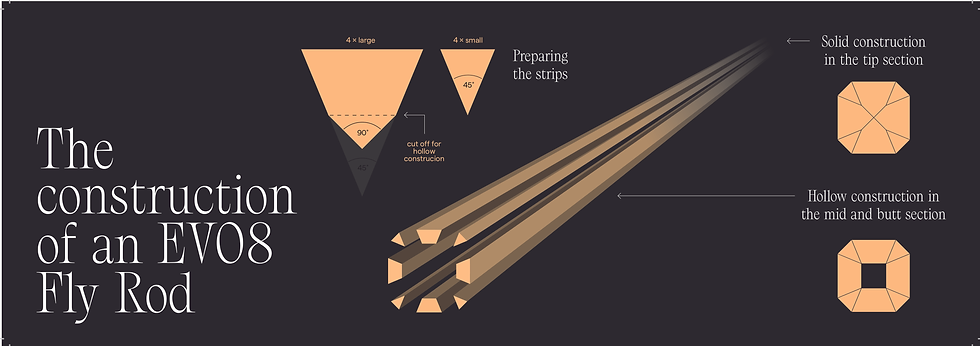

In order to achieve the same highest strength fiber density across the entire perimeter of the cross-section, the corners must be inserted.

The structure

The construction of an Evo8 is therefore extremely complex. Several work steps are necessary on the planing form (a different setting is required for each angle for the same rod section):

-

Setting the shape for the 45° taper of the large splice

-

Setting the shape for the 90° taper of the large splice

-

Setting the shape for the 45° taper of the small splice

-

Setting the shape for the (inner) taper of the wall thickness in hollow construction

This multiple adjustment of the mold for the same part makes it clear that the highest precision is required for all work steps; otherwise, nothing will fit together in the end, or intolerable glue joints will result.

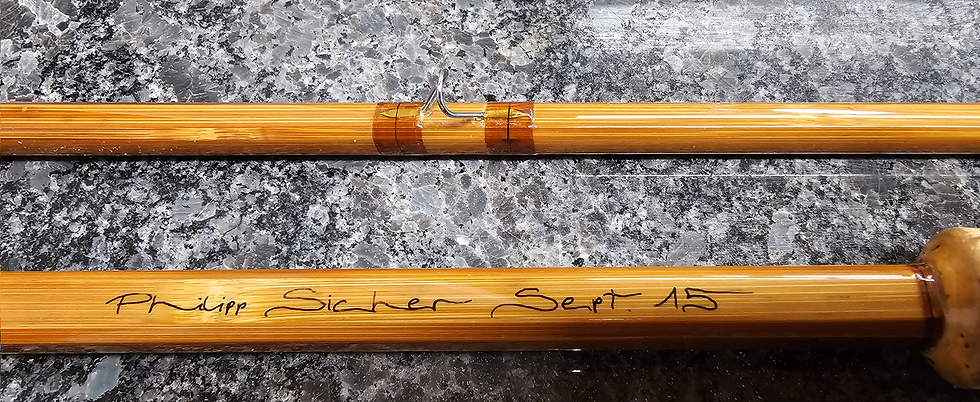

The real challenge lies in planing the small corner splices at the rod tip. The thinnest splices I've managed to plane on my Morgan Mill so far were just 0.25 mm. And to be honest, the real difficulty wasn't in planing the splices – assuming the blades were sharp – but in gluing them together.

Conclusion:

The Evo8 has some disadvantages:

-

complicated taper (re)calculation (multiple tapers in one rod)

-

Elaborate manufacturing process

-

large center splice with three tapers to plane (octa-quad-hollow)

-

high demands on precision

-

demanding gluing (tip)

-

special sleeves

-

too complicated for commercial production

but important advantages:

-

Combines the advantages of quad and octagonal rods (the rod's potential is significantly higher than that of a hexagonal rod, according to comparative tests).

-

Weight saving of 14–22%

-

elegant appearance (subjective)

-

Interesting rod with a high fun factor!!!

-

Rod building (thanks to the challenge) in its most beautiful form